Since we encounter a wide variety of problems, we have an equally wide range of engineering disciplines, many of which are highly specialized and designed to solve those problems.

Upgrade PLM practices and stay prepared for Digital Product Development

Increasing disruption in product ideation, design and delivery coupled with emerging concepts like 3D printing, Smart Manufacturing and Digital twin have opened a new era of product development and PLM processes. Wipro assists its customers in their PLM transformational journey through initiatives such as Digital PLM, Model Based Enterprise and Industry 4.0, helping them achieve faster time to market and deliver Next Gen products

Virtual ManTech helps enterprises create exponential business value by leveraging the power of software, data, connectivity, intelligence and other new-age technologies. Our digital engineering and manufacturing service experts help them design and build a robust digital engineering foundation with offerings for the entire product value chain.

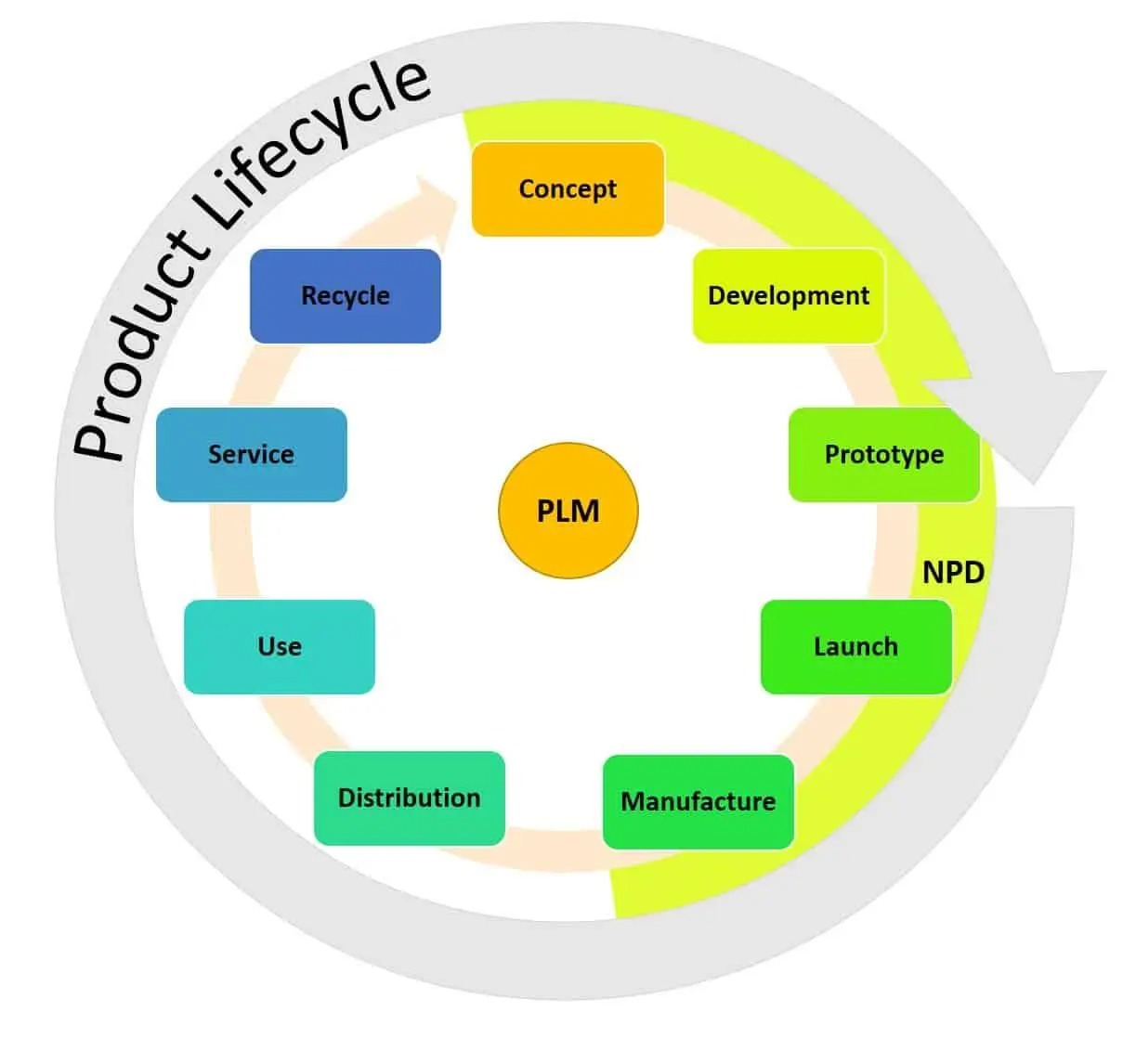

VIRTUAL MANTECH works with customers and complements their Product Engineering efforts by accelerating the adoption of new-age digital technologies, providing competencies and talent at scale, and leveraging best practices from unrelated industries. VMANF Tech services straddle the whole gamut of product life cycle management right from product conceptualization to product design and development, and from product support and sustenance to program management of specific processes such as release management and test automation.

Our Product Engineering services cover the whole spectrum from Software, Mechanical, Hardware, and VLSI design to industrial design, product benchmarking, and value engineering. Apart from helping customers in New Product Development Initiatives (NPDI), we partner with them in re-engineering their products to meet market demands in terms of cost, features, and performance.

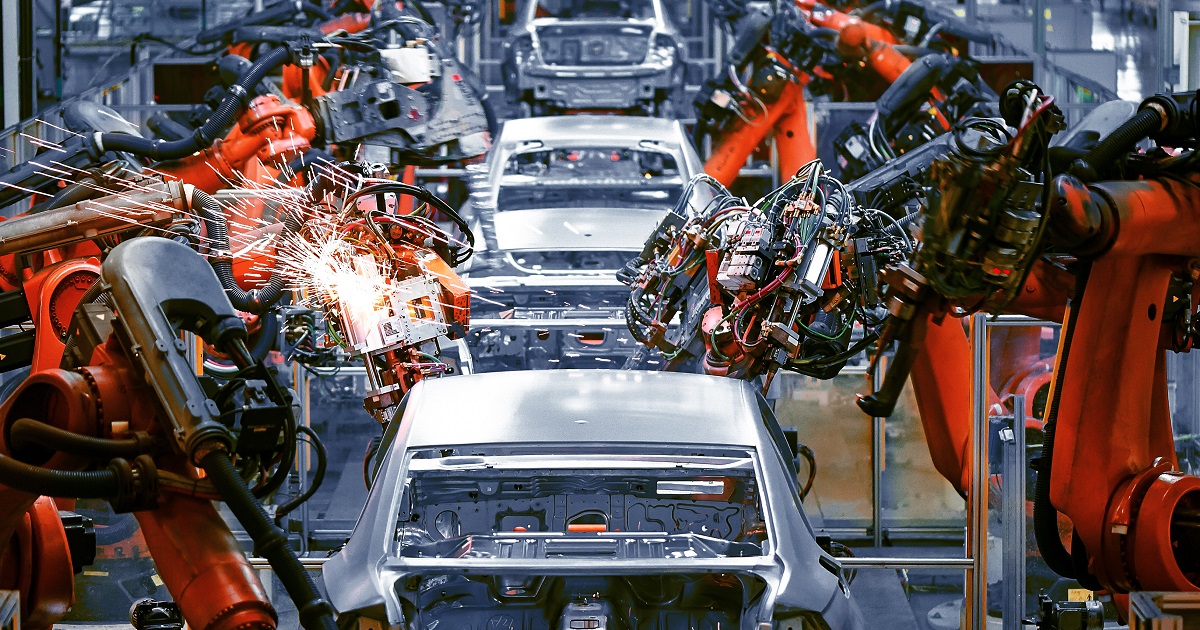

Virtual ManTech offers Industrial robot-based automation systems and robotics for a whole range of industries and applications. The experience of our teams, backed by a deep knowledge of the sector and new technologies, allows us to ensure our customers the best possible results in all kinds of robot programming projects.

PLC is responsible for controlling all the processes that take place in an industrial automation ecosystem. In order to be able to control, the PLC must be programmed with information about the processes that we want to automate.

What is Digital Twin?

A digital twin is a digital representation of a physical object, process, service or environment that behaves and looks like its counterpart in the real-world

A digital twin can be a digital replica of an object in the physical world, such as a jet engine or wind farms, or even larger items such as buildings or even whole cities, alternatively digital twin technology can be used to replicate processes in order to collect data to predict how they will perform

A digital twin is, in essence, a computer program that uses real world data to create simulations that can predict how a product or process will perform.

These programs can integrate the internet of things (Industry 4.0), artificial intelligence and software analytics to enhance the output. With the advancement of machine learning and factors such as big data, these virtual models have become a staple in modern engineering to drive innovation and improve performance.

In short, creating one can allow the enhancement of strategic technology trends, prevent costly failures in physical objects and also, by using advanced analytical, monitoring and predictive capabilities, test processes and services.